Clamping And Gripping Equipment For Automated Processing

Product Details:

- Condition New

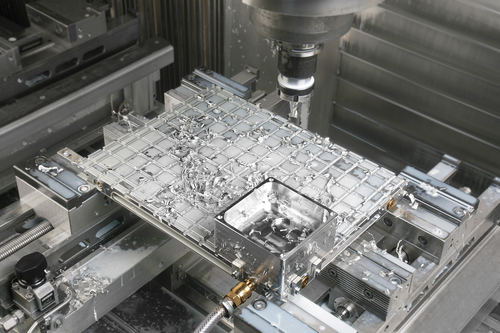

- Application Clamping Equipment for 3D Freeform Surfaces

- Click to View more

Clamping And Gripping Equipment For Automated Processing Price And Quantity

Clamping And Gripping Equipment For Automated Processing Product Specifications

- New

- Clamping Equipment for 3D Freeform Surfaces

Clamping And Gripping Equipment For Automated Processing Trade Information

- All India

Product Description

Clamping And Gripping Equipment For Automated Processing

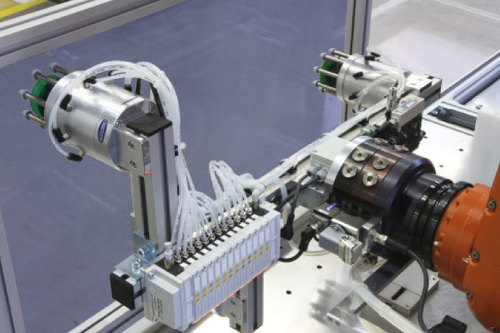

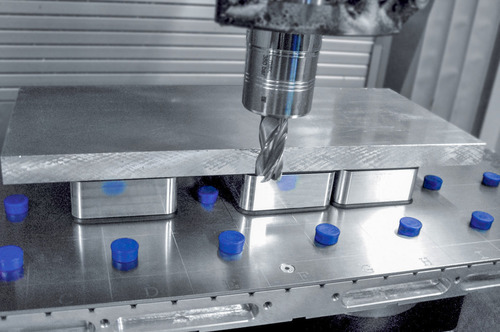

For more flexibility in automated production environments, Schmalz has developed the Suction Cup Balance SSCB A gripping and clamping system with automated conversion capability for 3D mould surfaces. With the same system, workpieces of different contours can be gripped and clamped - a great advantage in the automotive industry.

The Suction Cup Balance SSCB avoids expensive and lengthy conversion times It adapts flexibly to different and complex shaped components. This allows for smaller lot sizes to be produced in an economical manner. The system consists of a sturdy aluminium body with a vacuum and several compressed air connections. A flexible bellows suction pad from the resistant Vulkollan polyurethane elastomer is used in order to grip the workpiece. Around it, eight cylindrical positioning pins are arranged with wear-resistant bearing material for optimum adaptation to the respective 3D geometries.